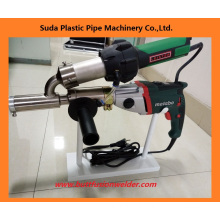

Hand Plastic Extruder Welding Machine

Basic Info

Model No.: SDJ610B

Product Description

Model NO.: SDJ610B Plastic Processed: PP, PVC, PVDF Feeding Mode: One Feed Screw: Single-Screw Automation: Automatic Hot Air Blower: Leister, Switzerland Preheating Air Volume: 500L/Min Frenquency: 50/60 Hz Trademark: SUDA Origin: China Type: Sheet Extruder Product Type: Extruder Welding Machine Assembly Structure: Integral Type Extruder Exhaust: Don′t Exhaust Computerized: Non-Computerized Drive Unit: Metabo, Germany Installation Guidline: Provide Video or Pictures Colour: Green Specification: CE ISO SGS HS Code: 84688000 Hand plastic extruder welding machine-SDJ610B

Please read operating instructions carefully before use and keep it for further reference.

SDJ610B Series Extruding plastic gun is a new type of hot air welder which imported foreign advanced technology.

Reasonable structure, convenient operation, continuous welding, high working efficiency, powerful extrusion, to make the weld strength is greatly improved,It is the idealproduct for a variety of thermoplastic welding processing.

Available welding materials: thermoplastic HDPE, PP, PVDF, especially PE .Don't apply in a conductive plastic(PEEL), or cause the machine to produce a conductive short-circuit.

Main technical parameters>>>

Operation procedures>>>

1) Put the welding gun on the shelf, install the handle, plug in the mains plug.

2) Open the control box switch, welding temperature is generally set at 300 ° C, Open the hot air machine power switch,thermostat knob, heated a few minutes to operate.

3) The right hand pull the motor switch, the motor starts to rotate. The new machines have noise, probably It mostly is relevant to the resonance between the tool and the base or the close of the parts inside the tool.If the motor is very smooth,and the internal sound disappears after sending welding rods.

4)The air temperature and air volumedetermine welding 's strength.Usually hot air temperature is 260 ~ 400 °

5)Hot air motor carbon brush life is about 800 hours, attention to early replacement, do not wait until the carbon brushes to run out.

6) When shutdown, please circumgyratehot air thermostat knob to the minimum, a few minutes blowing before they shut down the hot air machine.

Product Features>>>

1)Imported hot air welding torch and imported driven system, high temperature, big torque, long service life, stable performance.

2)Light weight, easy to handle and available to operation at different angles.

3)Big extrusion volume can be welded more than 10mm welding seam.

4)Different welding shoes can be applied to different types of welding.

5)It is used in the tank and pipe and comply with Part 4 of the DVS standard (Germany Welding Association).

Product warranty>>>

This welding machine warranty period from the date of delivery for one year.

Welcome your inquiry and sample order!!!

Suda Plastic Pipe Welding Machinery Co.,Ltd.

Contacts: Jenny

Mobile:0086-15064878065

Tel:0086-532-67735116

Fax:0086-532-66569132

Contact us if you need more details on Hand Extruder Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Extruder Welding Machine、Leister HDPE Plastic Hand Extruder Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Please read operating instructions carefully before use and keep it for further reference.

SDJ610B Series Extruding plastic gun is a new type of hot air welder which imported foreign advanced technology.

Reasonable structure, convenient operation, continuous welding, high working efficiency, powerful extrusion, to make the weld strength is greatly improved,It is the idealproduct for a variety of thermoplastic welding processing.

Available welding materials: thermoplastic HDPE, PP, PVDF, especially PE .Don't apply in a conductive plastic(PEEL), or cause the machine to produce a conductive short-circuit.

Main technical parameters>>>

| Model | SDJ610B |

| Voltage | 230V |

| Frequency | 50/60Hz |

| Extruding Power | Drive Motor 1100W |

| Hot air drive power | 3400W |

| Welding rod heating power | 800W |

| Wind Temperature | 20-600ºC |

| Heating temperature while plastic extruding | 200-300ºC |

| Welding speed | 2kg/h-2.5kg/h |

| Diameter of Welding Rod | ф3.0mm-4.0mm |

| Net Weight/Package Weight | 7.0kg/13.5kg |

| Motor Brand | Metabo |

Operation procedures>>>

1) Put the welding gun on the shelf, install the handle, plug in the mains plug.

2) Open the control box switch, welding temperature is generally set at 300 ° C, Open the hot air machine power switch,thermostat knob, heated a few minutes to operate.

3) The right hand pull the motor switch, the motor starts to rotate. The new machines have noise, probably It mostly is relevant to the resonance between the tool and the base or the close of the parts inside the tool.If the motor is very smooth,and the internal sound disappears after sending welding rods.

4)The air temperature and air volumedetermine welding 's strength.Usually hot air temperature is 260 ~ 400 °

5)Hot air motor carbon brush life is about 800 hours, attention to early replacement, do not wait until the carbon brushes to run out.

6) When shutdown, please circumgyratehot air thermostat knob to the minimum, a few minutes blowing before they shut down the hot air machine.

Product Features>>>

1)Imported hot air welding torch and imported driven system, high temperature, big torque, long service life, stable performance.

2)Light weight, easy to handle and available to operation at different angles.

3)Big extrusion volume can be welded more than 10mm welding seam.

4)Different welding shoes can be applied to different types of welding.

5)It is used in the tank and pipe and comply with Part 4 of the DVS standard (Germany Welding Association).

Product warranty>>>

This welding machine warranty period from the date of delivery for one year.

Welcome your inquiry and sample order!!!

Suda Plastic Pipe Welding Machinery Co.,Ltd.

Contacts: Jenny

Mobile:0086-15064878065

Tel:0086-532-67735116

Fax:0086-532-66569132

Contact us if you need more details on Hand Extruder Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Extruder Welding Machine、Leister HDPE Plastic Hand Extruder Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Hand Extruder

Premium Related Products

Other Products

Hot Products

63mm-160mm SDS160 Socket Fusion Welding MachineSde500 Electrofusion Pipe Welding EquipmentDl20-63mm Double Control PPR Welding MachineCNC PP/PE Plate Cutting SawAutomatic Plastic Sheet Cutting SawSudj3400A Hand Extruder Welding MachineDh2000 Plastic Sheet Welding Machine (DH2000)Electricfusion Welding MachineSud250m-4 HDPE Pipe Butt Fusion Welding MachineSud200m-4 HDPE Pipe Butt Fusion Welding MachineSud160/50 Best CNC Butt Fusion Welding MachineAutomatic CNC Plastic Sheet Rolling MachineSum90-315mm Workshop Welding MachinesSud315 HDPE Pipe Welding MachineAutomatic Plastic Butt-Welding and Bending MachineHigh Quaity 710-1000mm Multi-Angle Fitting Machine