Ninefold Profile Electric Cabinet Roll Forming Machine

Basic Info

Model No.: TG-0096

Product Description

Electric Cabinet Frame Machine Roller cold bending is when the metal strip passes through the rollers with several passes in turn, the rollers are fed forward along with the rotating strip of the rollers, and the rollers are continuously bent to obtain the desired section shape.Roller cold bending (Cold Roll Forming) is a plastic processing method for products with uniform cross-section and full-length through a number of different passes, local progressive bending deformation, full-section shape gradually approaching the cross-section shape of finished products.

The new generation section Nine Fold Profile Electric Cabinet Machine is with the advantages of high efficiency, safety, high accuracy forming precision. Nine Fold Profile Electric Cabinet Post Roll Forming Machine cancels many complicated operation and management process, such as shearing, slitting punching and bending, the efficiency be enhanced by 5-6 times composed with the traditional production process.

1. Profile Drawing and Products for Reference

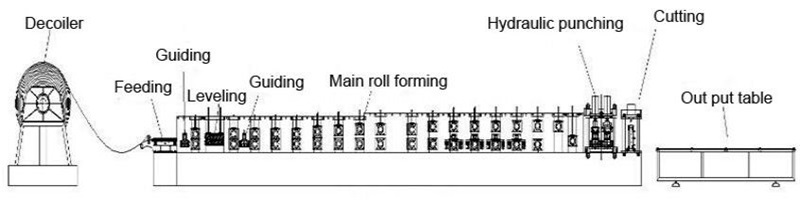

2. Working Flow of Nine Fold Profile Roll Forming Machine

2. Working Flow of Nine Fold Profile Roll Forming Machine

Decoiler---- feeding with guide--- Punching---- Roll forming---- Cutting---- Products collecting

3. Main technical data

| Suitable to process | Color steel plate, galvanized sheet,aluminum coils and etc. |

| Roller station | 20 rows |

| Thickness of feeding material | 1-3 mm |

| Productivity | 8-15m/min |

| Rollers' material | 45# forging steel |

| Cutting tool material: | GCr12 with quenched treatment 60-62°C |

| Weight | About 20T |

| Size | 20*2.4*1.8m |

| Voltage | 380V 50Hz 3phases |

| Main forming machine body | 300 mm H steel |

| Total power | 60kw |

4. Cabinet Frame Roll Forming Machine More details

(1) Manual Ue-coiler

Un-power: manual de-coiler; Max. Capacity: 5T

Suit for coil inner diameter: 508mm, suitable coil Max. out diameter: 1000mm

Manual power expands the coil inner surface.

(2) Flying saw Cutting

1) No stop cutting

2) The cutting blade material is Cr12 with quenched treatment

3) Adopts welded frame for good rigidity

4) Cutting frame has been heat treatment to avoid final product deformation. cutting length tolerance ± 2mm

5) The power of cutting is provided by hydraulic station

6) The final product can be CUT as per set length in PLC controller, and the length is automatically measured by encoder. When final product reaches the set length, machine will stop to cut the Product automatically. Finish this action, machine will run again continuously.

(3) PLC Control System

1) This system uses Delta PLC to control the all working actions. Production quantity and each piece length will be automatically measured. It is convenient to control the roll forming machine

2) Delta converter adjusts speed technology, realize the automatic production

3) Text screen is input and cancelled the working data

4) Friendly man-machine interface system can be set batches to the work piece, length, quantity, etc.

5) Encoder count, having function of count and measuring length

6) Suitable power voltage: 380V/50HZ/3Phase (can de designed according to buyer`s requirement)

5. Machine Overview

6. Scene application

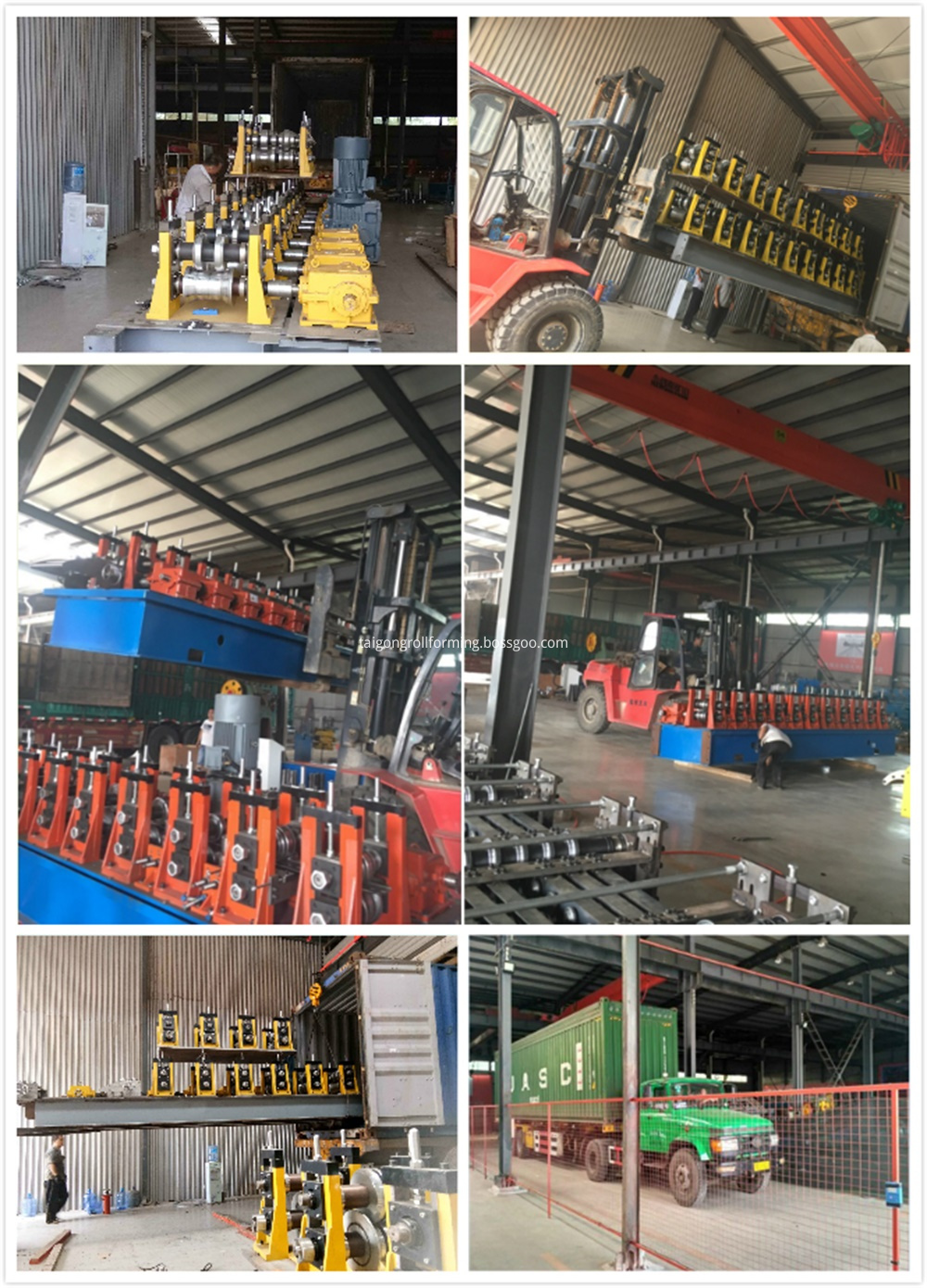

7. Customer

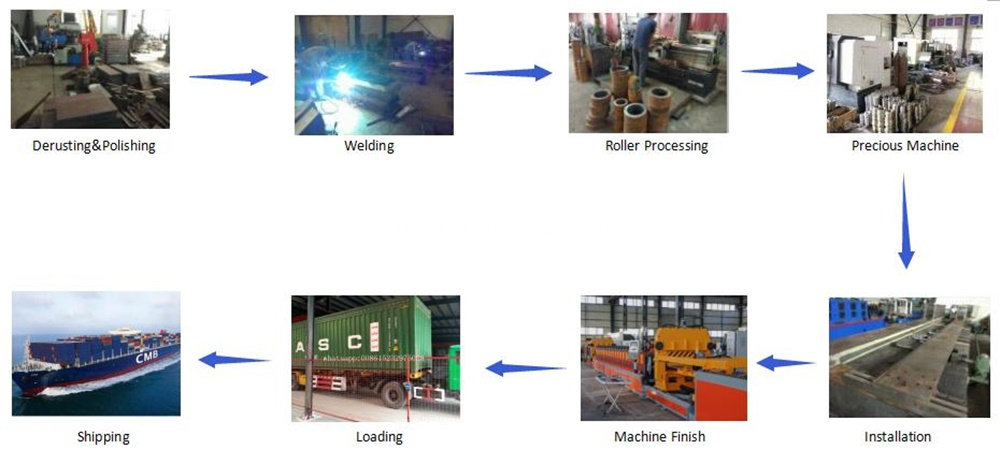

8. Loading

9. Our Services

1. Warranty :One year,and we will provide technical support for whole life of the Electric Cabinet Roll Forming Machine

2. Delivery time: Within 30 days after deposit receipt your payment

3. Guarantee period: 1 year free service/ pay service all the machine life

4. Installation and training If buyers visit our factory and check the Cabinet Frame Roll Forming Machine

we will teach you how to install and use the Electric Cabinet Machinery and also train your workers/technician face to face.

Without visiting,we will send you user manual and video to teach you to install and operate Electric Cabinet Machine

If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things.

Our main products include Stud Track Roll Forming Machines, Steel Frame Forming Machines, Purlin Roll Forming Machines, Welded Pipe Making Machines, Highway Guardrail Roll Forming Machines, Metal Expanded Mesh Production Lines and so on. If you have any further question of our Cold Roll Forming Machine, please feel free to contact me.

Contact us if you need more details on Cabinet Rack Enclosure Frame Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Electric Cabinet Rack Roll Forming Machine、Ninefold Profile Electric Cabinet Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Electric Cabinet Frame Machine > Nine Fold Profile Electric Cabinet Machine