Digital co2 gas gasless power 200 amp mma tig mig welder

Product Description

Product Description

Features

1. MIG & MMA function in one machine.

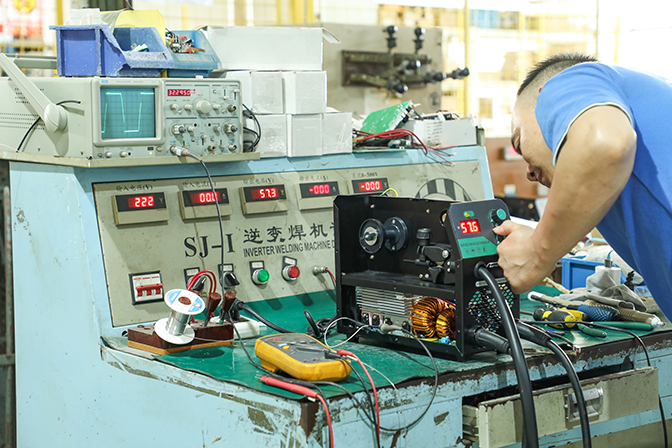

2. Advanced IGBT technology, compact design, lightweight, and energy saving.

3. Digital display, precisely controlled welding current, stable welding process, and excellent welding characteristics.

4. Automatic over-current, over-heat and over-voltage protection.

5. Integrated design with a wire feeder built-in. Facilitate mobility operations.

6. Can be used with gas or without gas.

7. Applicable for welding low carbon steel and low alloy steel of different thickness.

8. Compete with MIG torch, electrode holder, earth clamp, face mask, hammer.

2. Advanced IGBT technology, compact design, lightweight, and energy saving.

3. Digital display, precisely controlled welding current, stable welding process, and excellent welding characteristics.

4. Automatic over-current, over-heat and over-voltage protection.

5. Integrated design with a wire feeder built-in. Facilitate mobility operations.

6. Can be used with gas or without gas.

7. Applicable for welding low carbon steel and low alloy steel of different thickness.

8. Compete with MIG torch, electrode holder, earth clamp, face mask, hammer.

Digital co2 gas gasless power 200 amp mma TIG Mig Welder

Technical Specifications

ITEM | UNIT | MIG-140KT | MIG-160KT | MIG-180KT | MIG-200KT |

Input Power Voltage | V | AC230V±10% | AC230V±10% | AC230V±10% | AC230V±10% |

Input Power Frequency | Hz | 50/60 | 50/60 | 50/60 | 50/60 |

Rated Input Capacity | KVA | 3.8 | 4.5 | 5.3 | 6.1 |

Output Current Range (MIG) | A | 40-140 | 40-160 | 40-180 | 40-200 |

Output Current Range (MMA) | A | 20-120 | 20-140 | 20-160 | 20-180 |

Load Voltage | V | 16-21 | 16-22 | 16-23 | 16-24 |

Rated Duty Cycle | % | 60 | 60 | 60 | 60 |

Wire Feed Speed | M/min | 3-15 | 3-15 | 3-15 | 3-15 |

Gas Flow | L/min | 15-20 | 15-20 | 15-20 | 15-20 |

Dimensions | MM | 442*184*246 | 442*184*246 | 442*184*246 | 442*184*246 |

weight | Kg | 13.5 | 14 | 14.5 | 15 |

Related products

Company Introduction

Certifications

Exhibition

Action now

Why choose Retop?

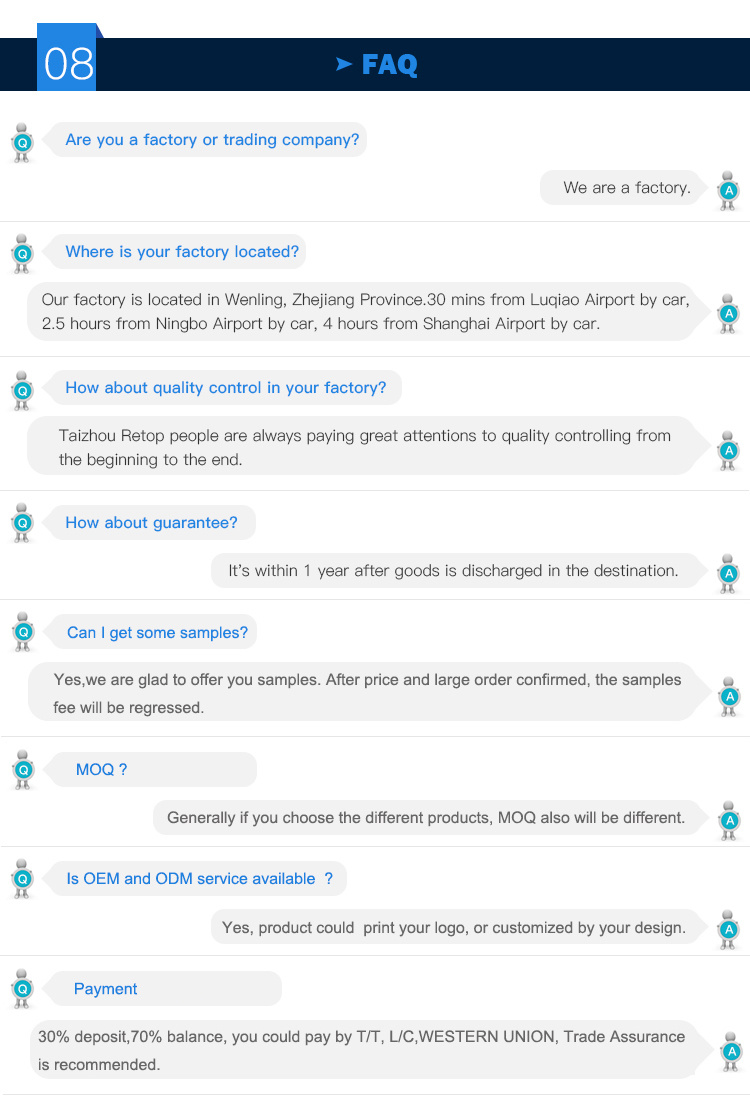

a. We are Welding Machine MANUFACTURER, so we can offer better price and after-sale service and shorter delivery date.

b. We use all new components,mosfet tube, diode, capacitor and so on imported components.

c. We adopt IGBT technology to decrease failure rate and it is convenient to repair the welding machine and reduce the cost of

repairing, we just need to change the bad pcb board.

d. We provide Warranty period of 1 year for all our items

a. We are Welding Machine MANUFACTURER, so we can offer better price and after-sale service and shorter delivery date.

b. We use all new components,mosfet tube, diode, capacitor and so on imported components.

c. We adopt IGBT technology to decrease failure rate and it is convenient to repair the welding machine and reduce the cost of

repairing, we just need to change the bad pcb board.

d. We provide Warranty period of 1 year for all our items

Product Categories : Other Selling Products > MIG

Premium Related Products

Other Products

Hot Products

63mm-160mm SDS160 Socket Fusion Welding MachineSde500 Electrofusion Pipe Welding EquipmentDl20-63mm Double Control PPR Welding MachineCNC PP/PE Plate Cutting SawAutomatic Plastic Sheet Cutting SawSudj3400A Hand Extruder Welding MachineDh2000 Plastic Sheet Welding Machine (DH2000)Electricfusion Welding MachineSud250m-4 HDPE Pipe Butt Fusion Welding MachineSud200m-4 HDPE Pipe Butt Fusion Welding MachineSud160/50 Best CNC Butt Fusion Welding MachineAutomatic CNC Plastic Sheet Rolling MachineSum90-315mm Workshop Welding MachinesSud315 HDPE Pipe Welding MachineAutomatic Plastic Butt-Welding and Bending MachineHigh Quaity 710-1000mm Multi-Angle Fitting Machine